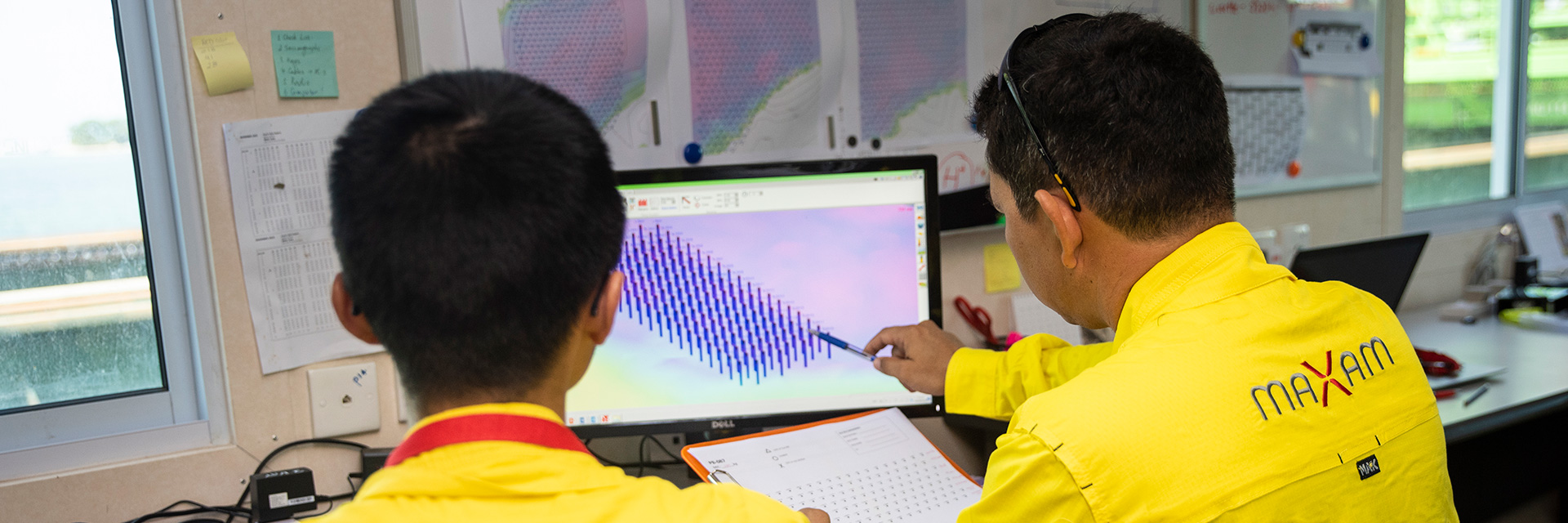

Safety

Safety is a core value at MAXAM an this why we work every day to improve our standards and support our customers in develop safer operations. In fact, we believe that the safest operation is the unmanned one, advancing with our digital capabilities to full automation of the industry.