“The Data Driven transformation of the blasting activities is key to maintain long term sustainable mining operations. MAXAM´s X-Energy features a series of technological innovations, all connected to ensure the proper use of our explosives energy to optimize the downstream outputs through digitalization” – Vicente Huélamo, MAXAM Technical Senior Advisor

Automation and digitalization of processes have the potential to improve safety, efficiency, and environmental impact in all mining operations. In an industry where data is being generated daily through digitized processes, Data Science methods are becoming instrumental to enhance decision making and guide the sustainability of the operations.

. Through a vertically integrated technology platform and with global production capabilities, at MAXAM, we work together with our customers to develop advanced adaptive solutions that ensure the safety, quality and environmental care, with the focus on improving the mine´s productivity and total cost reduction.

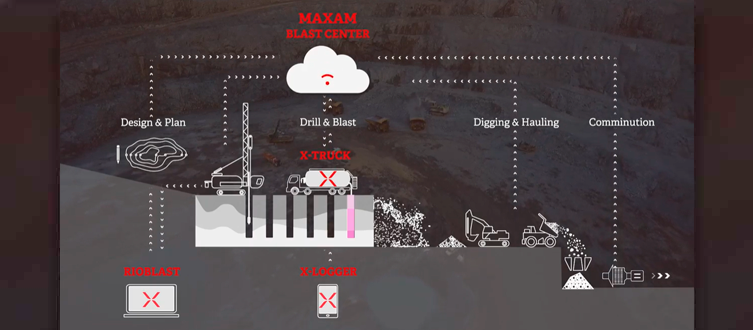

MAXAM Blast Center

MAXAM has developed a powerful and structured digital platform called MAXAM Blast Center, for storing, managing and sharing blast-related data. The platform is a user friendly, customized web-based system which can be accessed remotely.

Users can track information and generate reports resulting from blasting activities in real time, since the platform enables the full integration of MAXAM digital tools to design, plan and conduct efficient drilling and blasting operations. The MAXAM Blast Center can include downstream data from the mine to track and optimize drilling and blasting . The process starts with blast design information generated in RIOBLAST, MAXAM´s Blast Design Software, and transferred to the Blast Center platform. The blast design software, RIOBLAST takes into account rock characteristics [1] and blasting requirements to define the blast loading plans, timing configuration and the bulk explosive density profile for each specific rock layer along the borehole. The complete blast design is transferred to the Blast Center, from where it can be assigned to the specific MSU and the X-Logger. On the bench, the blaster can gather actual data with the X-Logger, such as stemming length and hole conditions, while the MSU loads the boreholes according to the blast loading plan. The actual loading data is transferred back to the Blast Center, where the information can be shared and processed. Innovative solutions using data science, Business Intelligence, Equipment Utilization and Blast Optimization can be developed as a consequence of the digitalization of blasting processes. The application of Artificial Intelligence and Machine Learning are key to generating value at each stage of the mine production cycle.

The new generation of MAXAM’s fully digitalized Mobile Sensitizing Units, X-TRUCK, represents the state-of-the-art technology for manufacturing and loading of bulk blasting products. The sensitizing and loading of explosives is an operation that requires the highest quality standards to achieve the desired results. MAXAM Blast Center ensures that the entire process, from blast design, data exchange, to final product application, and blasting outcomes, is consistently performed safely, correctly, and efficiently to always produce the optimum blasting outcomes. X-Truck offers a means of communication between the MAXAM Blast Center and the MSU control system. Loading plans can be sent directly to the loading units via a high-speed WiFi network, allowing each MSU manufacture the specified quantity of product and load it directly into each borehole.X-Truck

X- Logger

X-Logger is an application for portable devices designed to collect and digitize actual data on the bench, such as borehole parameters after drilling, amount of product loaded in each borehole, stemming control and others. This device is fully integrated into the MAXAM Blast Center, in a way that the data retrieved from the field is automatically updated in the platform, using internet connection. In the absence of an Internet connection, the data is synchronized when the connection is re-stablished.

The integration of geology, blasting design and drilling information into an innovative explosive application technology contributes to the mine optimization program. These optimization capabilities involve the ability to continuously model and measure all related phenomena and operational performance and consolidate them into a continuous improvement program of all the mine operations.