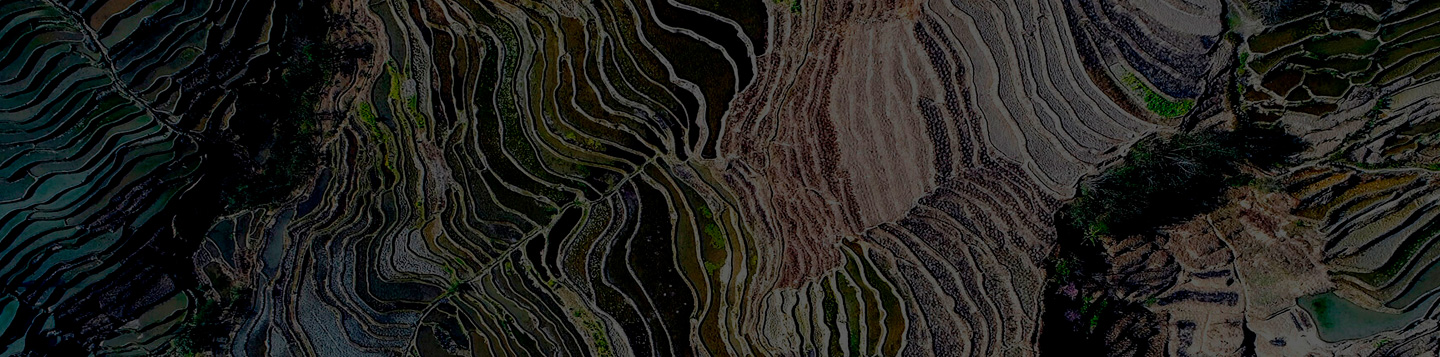

China: at full throttle towards mining productivity

With 4 million tons of explosives and 1.2 billion of detonators consumption per year -and growing-, China has become the largest civil explosive markets in the world.

Driven by strong business investment -and a sound governmental guidance to increase technology adoption-, the mining and infrastructure sectors have experienced notable modernization over the last years.

However, the Chinese industry still poses significant safety and environmental challenges. Also, the next frontier, once these basics are covered, will be increasing efficiency and productivity, as a key to achieve sustained growth.

December 2019

-

Safer mining by means of automation and ad-hoc technologies

Despite significant improvements over the past years, safety is still a clear concern for the Chinese mining industry. That is an undeniable truth. In fact, earlier this year, we all read about the decision of closing over 1,000 small mining sites due to safety concerns in 2019.

There’s room for improvement in the application of new technologies -such as aerial reconnaissance and digital simulation software- and in the automation of open-pit and underground operations. Also, China will benefit from the adoption of advanced global technologies in the field of permissible explosives, specially designed to increase safety in coal mines.

Greener manufacturing and greener in operations

Blasting providers can highly contribute to a green mining industry first and foremost through energy optimization: applying high energy explosives in blasting operations, the total use of energy -fossil fuels and electrical energy- is reduced, thus improving the C02 footprint.

Also, manufacturing activity needs to be optimized. In the case of MAXAM, in instance, we are especially mindful of the use of energy in the manufacturing of our cartridge watergel explosives, with considerably less energy consumption than other traditional explosives (emulsions).

The next frontier: significant productivity enhancements

Increase the productivity of operations will be of paramount importance. Some key solutions for optimal fragmentation, such as high-energy explosives, explosives of variable density, and advanced initiation systems providing accurate timing and wide range of delays, could highly aid on this target.

The 13th 5-year plan for the social and economic process of the People Republic of China, sets a clear path for the future. Watch here our conversation, discussing our role as a blasting solution provider to make the most of our strengths and capabilities in order to fulfill that agenda.

-

See the full story:

This was not an easy process, since our fleet operating with Teck differs considerably between the sites in the type, size and design. Also, time was a major concern. Today, the conversion process lasts between two to three weeks, which has an impact on the operation’s productivity.

In addition to reducing leaching, this solution also brought additional benefits such as avoiding contamination at the bottom of the blasthole since the liner protects also the booster. .On the other hand, it allows a better use of our explosives. The liner protects it from water and avoids filtration through cracks.

Of course, like all changes, there were many questions from blasters at the beginning, especially regarding safety. Once it was explained, addressed and we prove in the field that the process functioned as expected, they were quite impressed. The modifications are positive as it allows both operators and blasters to know where the hose is and have a better control of the hose reel.

In my belief, the more people that actually start to try and do this could get a much better system. We all have an environmental concern and it is a potential solution. We have gone from experimenting in a bathtub to receiving the contribution of many people to make this happen. To me, the benefit is not only the process but all those people actually working together. JEFF HAWLEY. TECK SENIOR ENGINEER SUPERVISOR, BUSINESS IMPROVEMENT

Today’s mining operations present many challenges in terms of productivity, efficiency, and sustainability and our experience has shown that the best answer to these challenges is co-creation, developing tailor-made solutions to specific problems.

-

Proud winners of the Mining Magazine Awards 2019

-

See the full story: